How To Write a Production Resume

Production work requires mechanical skills, a problem-solving mindset, and a strong grasp of workplace safety. Learn how to organize these and your other production skills into a cohesive resume with the tips and examples in this guide.

- Entry-level

- Mid-career

- Senior-Level

1. Craft an outstanding profile with a summary of your production qualifications

Start your resume with a brief summary of who you are as a candidate and how you meet the qualifications. List your job title, years of experience, and any skills or certifications in specific equipment. Also, describe your overall value to past employers, such as reducing new equipment purchases.

Senior-Level Profile Example

Computer numerically controlled (CNC) machinist with over 10 years of advancement and experience. Expertly restored and repurposed various machines, improving the bottom line by $125,000. Skilled at training new machinists and filling various plant needs, including heavy machinery operation.

Entry-Level Profile Example

Motivated machine operator with nearly three years in production. Frequently exceed production quotas in a fast-paced environment. Committed to workplace safety, with multiple awards for strong adherence to safety standards and practices. Working toward several National Institute for Metalworking skills certifications.

2. Add your production experience with compelling examples

The professional experience section of your resume will likely be the largest, so it needs to make a strong impact. Use this section to cover specific types of equipment you’ve worked on, parts you’ve replaced, and any other duties such as documentation or leading a team.

Senior-Level Professional Experience Example

Lead Machinist

General Dynamics Information Technology, Pawcatuck, CT | November 2018 to present

- Quickly solve issues with machinery, assembly, and equipment to help machinists and managers maintain productivity

- Read blueprints or job orders to obtain product specs and tooling instructions such as fixtures, feed rates, cutting speeds, depth of cut, and cutting tools

- Design fixtures, tooling, and experimental parts to meet special needs

- Evaluate other machinists’ work and offer suggestions where appropriate

Entry-Level Professional Experience Example

Machine Operator

Alternative Plastics, Gentry, AR | June 2022 to present

- Set up, operate, and maintain high-speed and precision machinery used in mass production

- Equip machines with all necessary tools and parts

- Work closely with team members to maximize profit and efficiency

- Keep records of approved and defective units or final products

3. Include education and certifications relevant to production

Production hiring managers usually care more about your experience than your education, but it’s still a good idea to include any degrees or certifications you’ve earned on your resume. The position may require a high school diploma (or equivalent), or a mechanical certification, so including these ensures the hiring manager knows you’re qualified.

Education

Template

- [Degree Name]

- [School Name], [City, State Abbreviation] | [Graduation Year]

Example

- Diploma

- Centennial High School, Bentonville, AR | 2019

Certifications

Template

- [Certification Name], [Awarding Organization] | [Completion Year]

Example

- Post-Secondary Certificate, National Institute for Metalworking On-The-Job Workshop | 2019

4. Outline your most useful production skills and proficiencies

Most production job openings specify the applicant’s skills to be considered. Include a key skills section on your resume so the hiring manager can quickly identify you as a good fit. Tailor your skills list to each job, which could mean citing specific equipment, OSHA safety standards, or process management methods. To help you brainstorm ideas, we’ve created the following list of common skills for production jobs.

| Key Skills and Proficiencies | |

|---|---|

| Complex problem-solving | Efficiency improvement |

| Equipment assembly | Measurement tools |

| Personnel training | Process streamlining |

| Quality assurance | Reading blueprints, schematics, and spec sheets |

| Reporting and documentation | Team collaboration |

| Workplace safety | |

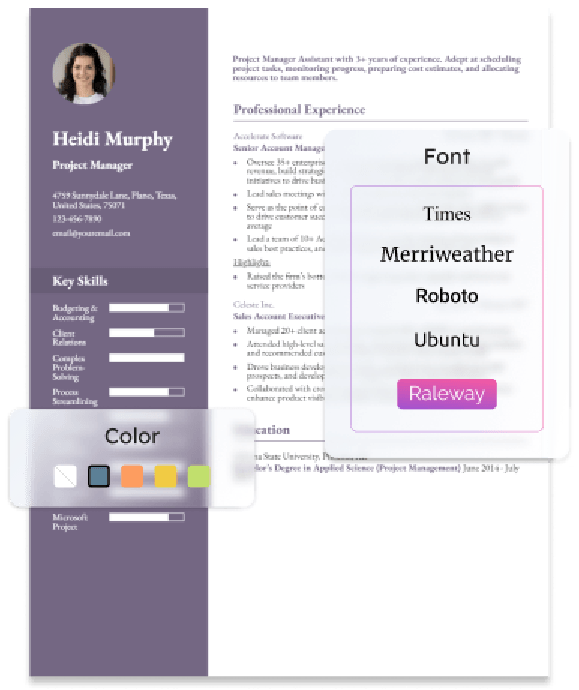

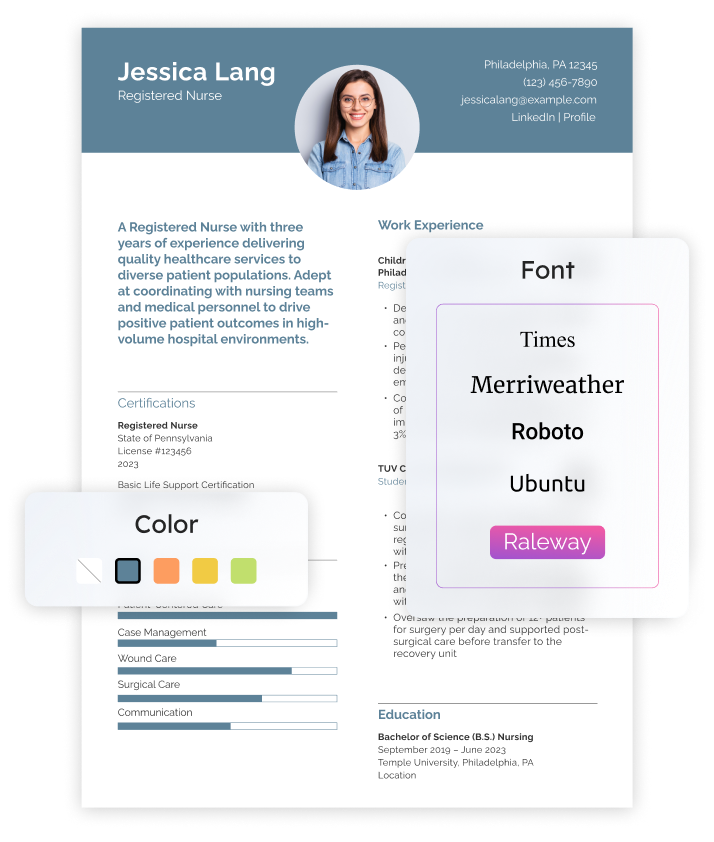

How To Pick the Best Production Resume Template

Writing a resume from scratch can feel daunting, so consider using a template to help you get started. Choose a template with space for your profile summary, professional experience, credentials, and skills. Production resumes should be well-organized, with clear headers and bullet points reading like a spec sheet of your qualifications.

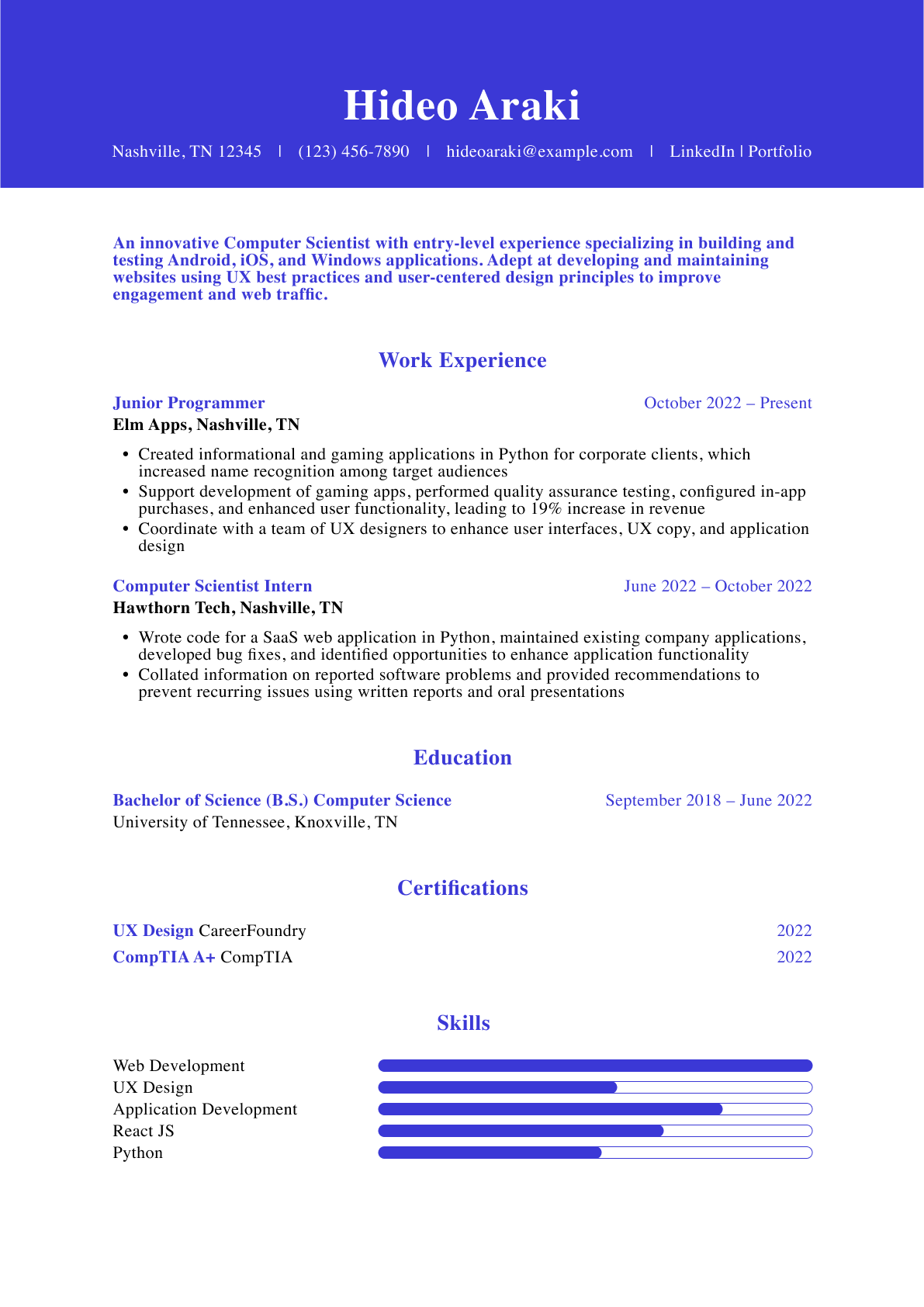

Production Text-Only Resume Templates and Examples

- Entry-level

- Mid-career

- Senior-level

Virginia Steele

(602) 888-8888

[email protected]

717 Mesa Blvd, Elizabethtown, KY 42701

Profile

Quality Control Technician sought out for efficiency and process recommendations based on strong assembly background. Won various awards including “Production Employee of the Month” on 3 occasions.

Key Skills

- Efficiency Improvement

- Quality Control (QC)

- Team Collaboration

- Technical Troubleshooting

Professional Experience

Assembler / Quality Control, Metalsa, Elizabethtown, KY | March 2019 to Present

- Frequently inspect production and packing areas to ensure correct product forms, specs, storage, packaging, labeling, and coding

- Recommend process changes to help optimize efficiency and quality

- Consult and advise design team on prototype testing

Highlight:

- Co-developed a new quality standards manual that helped better align the organization

Assembler, Ford Motor Company, Kansas City, MO | September 2016 to February 2019

- Assembled components by examining connections for proper fit and securing parts and subassemblies

- Fixed assembly issues by modifying dimensions to match

- Worked in different areas of the department as production schedule dictated

Highlights:

- Named “Production Employee of the Month” out of 250+ peers on 3 occasions

- Surpassed daily production quota by 10%+ on average

Assembler (night shift), Sedona Medical, Phoenix, AZ | June 2013 to August 2016

- Used hand tools and machines to assemble parts, closely following blueprints and schematics

- Ensured each part was fastened securely, and logged any deviations

- Performed hourly QC checks

Highlight:

- Exceeded production quota by ~1,500 units per day

Education

General Education Development (GED) Diploma | 2013

Frequently Asked Questions: Production Resume Examples and Advice

What are common action verbs for production resumes?-

Start each bullet point with an active verb when writing your job descriptions. Strong verbs make your resume more engaging and give the hiring manager a clear idea of your accomplishments in previous roles. See the below list of common action verbs for production resumes.

| Action Verbs | |

|---|---|

| Assemble | Construct |

| Control | Design |

| Engineer | Fabricate |

| Generate | Improve |

| Innovate | Inspect |

| Maintain | Measure |

| Operate | Prevent |

| Produce | Streamline |

| Supervise | Test |

| Update | |

How do you align your resume with a production job posting?-

The Bureau of Labor Statistics expects production jobs to be in shorter supply through 2031, but keep in mind this encompasses many positions. Some vocations, such as food processing equipment workers, are still expected to see average growth.

No matter your industry, you can improve your resume by tailoring it to each job opening. One great way to do this is by briefly describing the companies where you’ve worked in [brackets] right next to or below the company name.

Company descriptions let you show any similarities between your past employers and the one who posted the job. For example, maybe you’ve worked for companies of a similar size or product set. Or maybe you’ve worked at organizations with a similar mission or leadership philosophy. Working these details into your descriptions makes your resume more relevant to the job opening.

What is the best production resume format?-

Most production workers should use the combination (or hybrid) format. True to its name, this format combines two important features of other resume formats: the chronological format’s experience section and the functional format’s profile section. (The resume examples on this page all use combination format, as do most resumes on Resume Builder.)

By fusing these two features, a combination resume offers the best of both worlds. The experience section gives an overview of your recent work history – essential information for most employers. At the same time, the profile section lets you showcase your career highlights at the top, regardless if they’re from that work history or another part of your background.

The resulting resume is straightforward yet strategic. It gives hiring managers the clearest possible view of your experience and relevant strengths, so they can decide to call you for an interview.

Craft your perfect resume in minutes

Get 2x more interviews with Resume Builder. Access Pro Plan features for a limited time!